GENERAL INFORMATION ABOUT SCCL

The Singareni Collieries Company Limited (SCCL) - Pointwise Notes

Overview

- Ownership:

- Government-owned coal mining corporation.

- Under the Department of Energy, Government of Telangana.

- 49% ownership by the Ministry of Coal, Union Government of India.

- Chairman & Managing Director: Sri N.Balram,IRS

- Operations:

- Operates 45 mines (20 opencast and 25 underground).

- Located in 6 districts of Telangana.

- Employs around 45,079 people as of November 2020.

- Contributes 9.2% to India's domestic coal production.

- Production and Reserves:

- Extracted 1.36 billion tonnes (BT) of coal since inception.

- Proven reserves of 10.84 BT.

- SCCL Future Targets

SCCL has a vision for 2023–24 to reach:

Ø Production and Dispatches of 85.00 Metric Tons

Ø Over Burden Removal of 600 Million Cubic Meters

Ø Gross sales of Rs. 340 billion

Ø Profit of Rs. 25 billion

Ø Power generation of 2,500 Megawatts

History

- Discovery:

- Coal discovered in 1871 by Dr. William King of the Geological Survey of India near Yellandu in Khammam district.

- Initial Development:

- The Hyderabad (Deccan) Company Limited acquired mining rights in 1886.

- Incorporated as SCCL on 23 December 1920.

- Ownership Changes:

- State of Hyderabad purchased majority shares in 1945.

- Managed by Industrial Trust Fund from 1949.

- Became a government company under the Companies Act in 1956.

- Agreements:

- Four-party agreement (10 June 1974) and subsequent agreement (13 December 1977) for financial assistance.

- Tripartite agreements for various plan periods (VI to X) from 1985 to 2010.

Operations

- Geographical Spread:

- Operations in Komaram Bheem, Mancherial, Peddapalli, Jayashankar Bhupalpalli, Bhadradri Kothagudem, and Khammam districts.

- Coal Reserves:

- Godavari valley coalfield has 22,016 million tonnes of coal reserves.

- Includes proven, indicated, and inferred reserves up to a depth of 1,200 meters.

- Extraction Data:

- Extracted 929.11 million tonnes of coal up to the year 2009-10 from the Godavari valley coalfield.

SCCL Milestones in Introducing New Technologies

- 2020: 300 MW Captive Solar Power Plants

- Started generating solar power for captive use.

- 2016: 2 X 600 MW Thermal Power Plant

- First government coal company to generate thermal power for commercial use.

- 2015: Mine Cruiser

- Introduced for efficient transportation within mines.

- 2014: High Capacity Longwall (LW) at Adriyala

- Implemented for enhanced underground mining efficiency.

- 2011: Processed Over Burden at Bhupalpally

- Used as stowing material in underground mines as an alternative to scarce river sand.

- Won the "Golden Peacock Innovative Product/Service Award" in 2015 at Dubai.

- 2010: High Wall Mining

- Adopted advanced mining technique for extracting coal from the high walls of open-pit mines.

- 2009: Light Weight Cap Lamps

- Implemented in all underground mines for better visibility and safety.

- 2008: Diesel Operated Underground Machinery

- Introduced for improved mining operations.

- ERP (SAP) implemented, making SCCL the first government coal company to introduce SAP.

- 2007: 3D Laser Scanner

- Used for precise mine surveying.

- 2003: Phasing Out Manual Coal Filling

- Launched to enhance automation in coal filling processes.

- 2002: Man-Riding System in Conventional Mines

- Reduced travel time and fatigue for workmen.

- 1994: In-pit Crushing and Conveying

- Introduced for efficient coal handling.

- 1989: French Blasting Gallery Method

- Adopted for safer and more effective blasting in mines.

- 1986: Walking Dragline

- Implemented for large-scale excavation in open-cast mines.

- 1983: Long Wall Mining

- Adopted for high productivity underground mining.

- 1981: Load Haul Dumpers and Headers

- Introduced for mechanized underground mining.

- 1979: Side Discharge Loaders

- Implemented for improved material handling in mines.

- 1975: Open Cast Mining

- Expanded surface mining operations.

- 1954: Flame Proof Electric Equipment

- Introduced for enhanced safety in explosive environments.

- 1953: Electric Cap Lamps

- Enhanced visibility for miners.

- 1951: Electric Coal Drills

- Improved drilling efficiency in mines.

- 1948: Machine Mining (Joy Loader and Shuttle Cars)

- Early mechanization in coal mining.

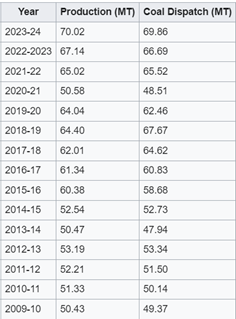

SCCL Production and Dispatch (2023-2024)

- Production: 70.02 million tonnes (MT)

- Coal Dispatch: 69.86 MT

- Overburden (OB) Removal: 420.32 million cubic meters (M.Cu.Mt)

- Employees: 41,837

Historical Production Data

- 2016-2017: Production - 61.34 MT, Coal Dispatch - 60.83 MT, OB Removal - 315.00 M.Cu.Mt, Employees - 56,282.

- 2007-2008: Production - 40.60 MT, Coal Dispatch - 41.79 MT, OB Removal - 140.72 M.Cu.Mt, Employees - 75,573.

Technology-Wise Coal Production (2019-2020)

- Underground Mining: 8.66 MT

- Open Cast (OC) Mining: 55.37 MT

- Total Production: 64.04 MT

Grade-Wise Coal Production

- G1 (Above 7000 K.Cal/Kg): Negligible

- G9 (4601 - 4900 K.Cal/Kg): 12.5%

- G10 (4301 - 4600 K.Cal/Kg): 17.5%

- G11 (4001 - 4300 K.Cal/Kg): 18.7%

Coal Off-take Sector Wise (2017-2018)

- Power (Utility): 53.88 MT

- Power (Captive): 2.78 MT

- Cement: 2.57 MT

- Other: 6.27 MT

Quality and Washing of Coal

- Third-Party Sampling: Introduced with NTPC in 2016, now with all power consumers.

- Coal Washeries: 3 operational with 1 MTPA capacity each; two more with 7 MTPA total capacity in the pipeline.

Power Generation

- 2 X 600 MW Thermal Power Plant at Jaipur, Mancherial district.

- Unit 1 COD: 25.09.2016

- Unit 2 COD: 02.12.2016

New Mines and Capacity Addition

- 14 new mines planned (6 underground, 8 opencast) with a capacity addition of 52.37 MT in the next 5 years.

Recent Mine Openings

- 2017-2018: 3 mines, 13.50 MTPA capacity.

- 2016-2017: 2 mines, 2.50 MTPA capacity.

SCCL Future Targets (2023–24)

- Production and Dispatches: Aim to reach 85.00 million metric tons.

- Over Burden Removal: Target of 600 million cubic meters.

- Gross Sales: Projected to achieve Rs. 340 billion.

- Profit: Expected to reach Rs. 25 billion.

- Power Generation: Plan to generate 2,500 megawatts.

Awards and Recognition

- India's Best Company Award.

- Asia Pacific Entrepreneurship Award 2018 from Enterprise Award.

- National Award for Excellence in Cost Management 2016 (Large Mining PSUs Division) from the Institute of Cost Accounts of India.

- Golden Peacock Innovative Product/Service Award 2015.

- Indira Gandhi Vriksha Mitra Award 2004 for afforestation and waste land development.

- Environmental Excellence Award 2005-06 from SRISTI, New Delhi.

- Environmental Excellence Award 2005-06 from Green Tech Foundation.

- Golden Peacock Innovation Management Award 2005 from the Institute of Directors, New Delhi.

- Golden Peacock Environment Management Award 2005 from World Environment Foundation, New Delhi.

- National Fly Ash Utilization Award 2005 jointly from the Ministry of Environment and Forests, Power and Science and Technology, Government of India.

- Second Best Corporate Film Award 2005 by Public Relations Society of India, Hyderabad for "Shramika Bandham".

- National Safety Awards (Mines) 2004 (for 2001) by the Directorate General of Mines Safety, Government of India.

- Best Workers Welfare Activity Award 2003-04 by FAPCCI.

- Best Overall Performance Award 2002-03 by FAPCCI.

- Best Management Award 2001-02 by the Government of Andhra Pradesh.

Operations

- Coal Extraction Region: Operates in Telangana, specifically in the Pranahita-Godavari Valley region.

- Coal Reserves: Estimated at 879 billion tonnes.

- Ramagundam Divisions:

- Three divisions: RG-1, RG-2, RG-3, and the Adriyala project area.

- Each division is headed by a General Manager.

- Thermal Power Plant:

- 1,200 MW (2 X 600 MW) plant established in Jaipur, Srirampur region, Mancherial district.

- Proposal to establish an additional 800 MW unit at the Jaipur power plant.

- Solar Power Plant:

- Plan for a 300 MW solar power plant for captive use in coal mining areas.

- Coal Mines Provident Fund Offices:

- Located in Kothagudem, Ramagundam, Godavarikhani, and Hyderabad.

- Serve the needs of 4 regions.

No comments added yet!