Tele-monitoring systems and their features for use in underground coal mines

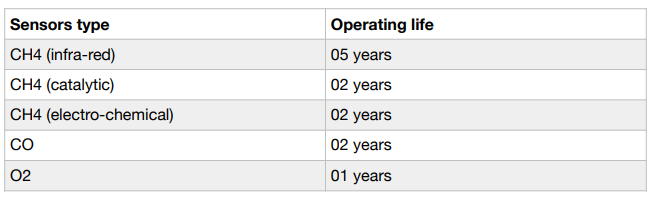

Tele-monitoring system is used for continuous monitoring of inflammable / toxic gases, air velocity etc. 1. Basic components of a Tele-monitoring system : • audio visual warning device • surface monitoring system for display, storage and retrieval of readings • power supply system • electrical power tripping arrangement • connected data transmission cable 2. Various parameter of the sensors : (a) minimum operating life of a sensors shall be as follows.

(b) working limit of temperature - not more than 50°C working limit of humidity - upto 100% (c) Calibration :

(i) deviation of the measured gas concentration shall not be more than 03% for all sensor types when tested with standard gases

(ii) interval of calibration of the sensor shall not exceed 03 months, alternating between

the OEM and the user. However OEM shall examine the tele-monitoring system totally at

least once every 06 months

3. Minimum required power back up in case of power failure shall be for a period of 04

hours.

4. Alarm system :

Minimum intensity of the audio part of the audio visual alarm provided with the telemonitoring system shall be 90 dB(A)

Use and care of local methane detectors in underground coal mines

Local Methane Detectors (LMD) are now being installed in underground coal mines for

monitoring the make of inflammable gases and for initiating suitable mitigating measures

well in advance before the concentration assumed dangerous properties.

1.0 Various components which make a LMD : LMD shall include the following as

essential basic components : A CH4 sensor unit.

FLP housing for the electrical circuit and a display unit of the detecting and measured CH4 concentration. The FLP housing may be integrated with the sensor unit. It shall be of an approved type, and shall accommodate arrangements for battery backup and coupling the LMD with power supply system of the ventilating district.

An audio-visual warning alarm unit. 2.0 Life of sensor used in in LMDs and their operating limits in term of temperature and relative humidity : The life of sensor used in the LMD shall be at least three (03) years. The sensor shall operate satisfactorily at the temperature up to 50°C and a relative humidity of up to 100%.

3.0 Place of installation of the LMD : The LMD shall be installed in the return airway of the district, as close as practically possible to a well supported roof as may facilitate clear observation of the display unit.

4.0 Type of electrical interlinking necessary with the LMD : Every LMD shall have provision of a suitable outlet for coupling it with the electrical supply system of the ventilating district by approved cables, connectors and other electrical accessories. That tripping circuit of LMD shall be electrically interlocked with power supply system of the connected working so as to cut off power supply when concentration of inflammable gases exceed a preset value.

5.0 Power backup with the LMD : Minimum required power backup in the event of disruption of main electrical power supply shall be for a period of 60 minutes. It shall be provided by a battery preferably of rechargeable type and with a minimum life of 12 months from the date of dispatch of the battery. Whenever there is a no battery backup, the same shall be incorporated within a period of six (06) months.

6.0 Levels of audio-visual alarm to be provided in terms of intensity : The audio level of the audio-visual alarm shall be at least 85 dB(A). The visual alarm shall consists of a cluster of LEDs or other suitable arrangements as may be distinctly visible from at least two opposite directions.

7.0 Frequency of calibration of sensors and other components : Maximum interval of calibration of the sensor shall not exceed three (03) months, alternating between the OEM and the user. All other calibration shall be done by the OEM.

8.0 Type of back-up service required for proper upkeep of the system for reliability :

The OEM shall examine the LMD in totality at least once every six (06) months.

(Cir Tech

14/2009)

No comments added yet!